CNC ngetok Straight suling ketok Solid carbide ketok pikeun beusi tuang coolant ketok

- Panjelasan Produk

Pikeun pangguna anu ngagaduhan syarat ngagunakeun coolant nalika ngolah, keran karbida coolant internal tiasa dilengkepan pikeun ningkatkeun umur alat.

OPT nyadiakeun internal coolant carbide taps na coolant samping coolant taps coolant, éta gumantung kana hiji requst pamaké.

liang coolant ngagaduhan tujuan anu penting pikeun manjangkeun umur alat tina keran karbida.

Firstly, liang coolant internal langsung coolant langsung ka edges motong, ngurangan hawa motong sarta gesekan.Ieu mah ngan saukur mantuan dina nyegah overheating tina ketok tapi ogé ngaronjatkeun évakuasi chip.

Bréh, ayana liang coolant samping nyebarkeun coolant sabudeureun shank ketok, salajengna ngurangan akumulasi panas tur panjang umur ketok urang.

- aplikasi has

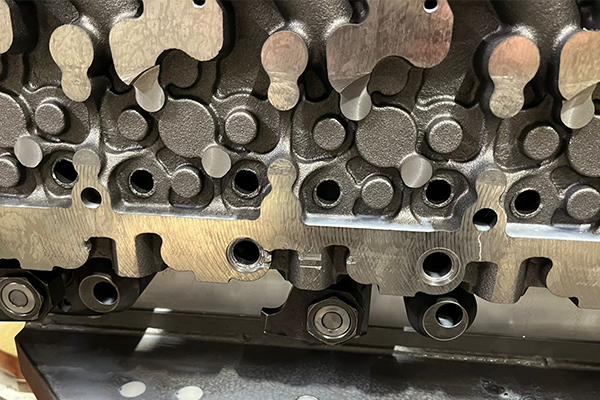

Salah sahiji aplikasi has tina keran carbide nyaéta dina mesin tuang sirah silinder mesin beusi.Hulu silinder ieu maénkeun peran pivotal dina kinerja sakabéh jeung durability mesin.Kalayan aplikasi keran karbida, produsén ngahontal akurasi benang anu unggul, nyababkeun sipat sealing anu ditingkatkeun sareng ngirangan kamungkinan bocor.Sumawona, umur alat anu diperpanjang tina keran karbida ngamungkinkeun produksi masal anu efisien bari ngajaga standar kualitas anu konsisten.

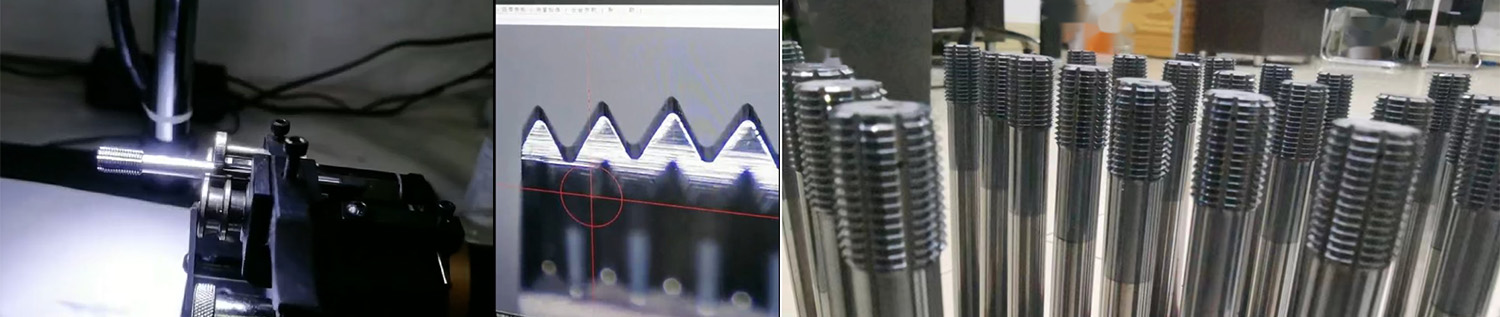

Inspeksi sareng tampilan

Sateuacan mesen, mangga komunikasi sareng layanan palanggan pre-jualan kami:

1. Bahan workpiece

2. Naha produk permukaan dirawat sanggeus ngolah

3. Syarat akurasi, ukuran go gauge sareng henteu go gauge.

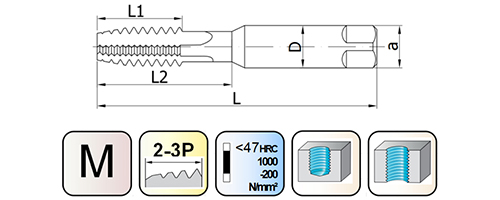

| Sebutan D | Ukuran benang | Jangkungna mm | L1 mm | L2 mm | D mm | L mm | Z | a ¨ | Pra-bor mm |

| T602-040048-M3x0.5 | M3 | 0.5 | 11 | 18 | 4 | 48 | 4 | 3.15 | 2.46-2.59 |

| T602-040050-M3.5×0.6 | M3.5 | 0.6 | 13 | 21 | 4 | 50 | 4 | 3.15 | 2.85-3.01 |

| T602-050053-M4x0.7 | M4 | 0.7 | 13 | 21 | 5 | 53 | 4 | 4 | 3.25-3.42 |

| T602-060058-M5x0.8 | M5 | 0.8 | 16 | 25 | 6 | 58 | 4 | 4.5 | 4.14-4.33 |

| T602-060066-M6x1 | M6 | 1 | 19 | 30 | 6 | 66 | 4 | 4.5 | 4.92-5.15 |

| T602-080072-M8x1 | M8 | 1 | 22 | 35 | 8 | 72 | 4 | 6.3 | 6.92-7.15 |

| T602-080072-M8x1.25 | M8 | 1.25 | 22 | 35 | 8 | 72 | 4 | 6.3 | 6.65-6.91 |

| T602-080080-M10x1 | M10 | 1 | 24 | - | 8 | 80 | 4 | 6.3 | 8.92-9.16 |

| T602-100080-M10x1 | M10 | 1 | 24 | 38 | 10 | 80 | 4 | 8 | 8.92-9.16 |

| T602-080080-M10x1.25 | M10 | 1.25 | 24 | - | 8 | 80 | 4 | 6.3 | 8.65-8.91 |

| T602-100080-M10x1.25 | M10 | 1.25 | 24 | 38 | 10 | 80 | 4 | 8 | 8.65-8.91 |

| T602-080080-M10x1.5 | M10 | 1.5 | 24 | - | 8 | 80 | 4 | 6.3 | 8.38-8.67 |

| T602-100080-M10x1.5 | M10 | 1.5 | 24 | 38 | 10 | 80 | 4 | 8 | 8.38-8.67 |

| T602-100089-M12x1.25 | M12 | 1.25 | 29 | - | 10 | 89 | 4 | 8 | 10.65-10.91 |

| T602-120089-M12x1.25 | M12 | 1.25 | 29 | 46 | 12 | 89 | 4 | 10 | 10.65-10.91 |

| T602-100089-M12x1.5 | M12 | 1.5 | 29 | - | 10 | 89 | 4 | 8 | 10.38-10.67 |

| T602-120089-M12x1.5 | M12 | 1.5 | 29 | 46 | 12 | 89 | 4 | 10 | 10.38-10.67 |

| T602-100089-M12x1.75 | M12 | 1.75 | 29 | - | 10 | 89 | 4 | 8 | 10.11-10.44 |

| T602-120089-M12x1.75 | M12 | 1.75 | 29 | 46 | 12 | 89 | 4 | 10 | 10.11-10.44 |

| T602-120095-M14x1.5 | M14 | 1.5 | 30 | - | 12 | 95 | 4 | 10 | 12.38-12.67 |

| T602-120095-M14x2 | M14 | 2 | 30 | - | 12 | 95 | 4 | 10 | 11.84-12.2 |

| T602-120102-M16x2 | M16 | 2 | 32 | - | 12 | 102 | 4 | 10 | 13.9-14.2 |